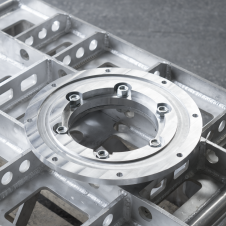

COMPLEX METALWORKING USING MODERN EQUIPMENT BY EUROPEAN QUALITY STANDARDS

-

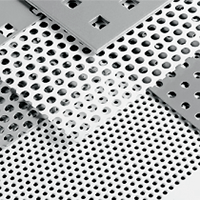

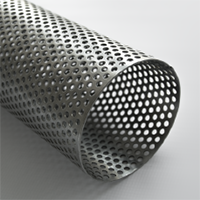

All main technologies of metalworking

-

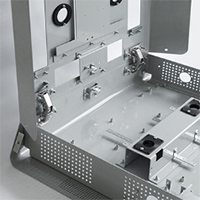

Complex approach

-

Solution of the most difficult tasks

-

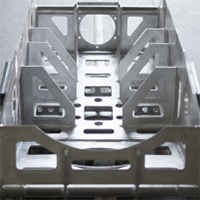

Highly qualified specialists with expertise in different areas of mechanical engineering (special-purpose equipment, load carriers, power industry, instrument engineering, etc.)

-

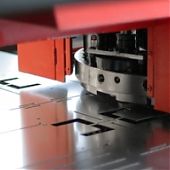

Japanese and German up-to-date metal-working equipment

-

Private equipment fleet

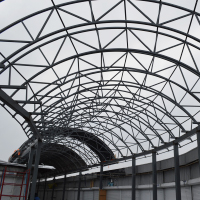

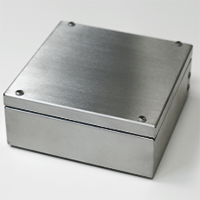

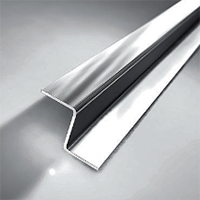

Sinergia Metalworking Factory has started its development from launching a small plastic and metalworking shop in 2003. Constantly improving and developing, our factory has become the largest metalworking enterprise in sheet metal and bar sections manufacturing in the Northwest Region. Today we provide full cycle manufacture from design development to making prototypes and their serial manufacture. Having all the resources required, the factory is able to manufacture products of any complexity: from individual parts to assemblies consisting of many items.

Today we have a vast experience in high-tech metalworking. We have a team of professionals, and a fleet of equipment of the best world manufacturers such as TRUMPF, AMADA, DMG, EWM, MERKLE, KEMPPI, DALEX, which allows to produce high-quality products, expand the range of products, and respond flexibly to changes in the market conditions.

The factory has its own equipment fleet with an area of about 2 hectares. There are industrial, warehousing and office buildings with a total area of 10,000 m2 on its territory, some of which are leased to partner enterprises.

Sinergia cooperates with small, medium and large Russian enterprises. It is also a first-class supplier for the largest transnational engineering corporations such as SIEMENS, SCANIA, CATERPILLAR and CLAAS.

Highly qualified personnel in all divisions and departments, up-to-date equipment, multilevel quality control, efficient production process, as well as compliance with ISO 9001 standards guarantee a permanently high quality of supplied products and short lead time.

LET’S BECOME PARTNERS!

CEO

DMITRY SORETS

f u ll c y c l e m e t a l w o r k i n

g

f u ll c y c l e m e t a l w o r k i n

g